automated r&D & data acquisition System 1

Project summary:

A manufacturing company in Markham, Toronto builds commercial refrigerators and freezers that make up a large lineup of products catering to the food and beverage industry.

An important component of the operations of this manufacturing plant was their R&D lab. In this lab, engineering concepts and ideas were conceived, engineering prototypes were experimented and final products were tested and certified.

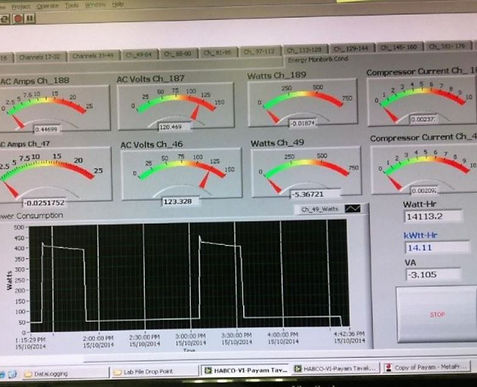

In every test for every product, for certification or as part of the design process, a large number of physical phenomenon needed to be measured, recorded and graphed so that the results could be then analyzed and/or reported to the certification agencies. For every test tens of transducers were used to measure physical phenomenon such as temperature, pressure, voltage, current, electrical energy consumption and air velocity.

A capable (in terms of accuracy and processing speed) stationary data logging network made up of data acquisition hardware, variety of sensors, power sources, software and an interface was needed such that this system could ultimately receive and record all the measurements.

.jpg)

Challenges:

A specific ASHRAE Energy Star test that applies to the commercial reach-in refrigeration industry was routinely performed. As part of this specific Energy Star test, a refrigerator had to be filled with test bottles with their temperatures being recorded by thermocouples.

For a period of 8 hours, every 10 minutes, the refrigerator's door had to be fully opened, remained opened for 6 seconds and then closed. The electrical energy consumption of the refrigerator had to be recorded the entire time while the average test bottle temperature had to remain below a certain limit.

The challenge was at this manufacturing company there were no means of performing this test automatically which aside from causing frustration consumed significant employee time.

End result:

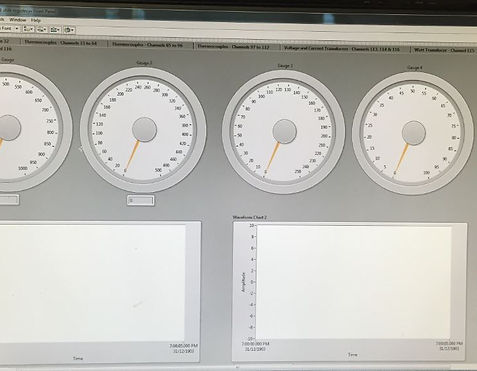

Work was started by conceiving the right hardware selection taking into account the number and type of sensors, processing speed requirements, accuracy and etc. National Instruments equipment were chosen due to their ease of integration with PC, hardware capability and HMI design tools. All the hardware and wiring between the NI equipment, power sources and transducers were completed. Next, programming the software and the interface were completed to ensure the system can both communicate with all the various transducers and lab technicians can start and stop tests and view live data being recorded.

A custom made electrical panel was built and custom connection bezels specific to the transducers being used were installed in the panel. All wiring from the electrical panel to the data logging station located outside the chamber were also completed. And the data logger was programmed such that on the desktop interface, with a click of a button the real time data from different physical phenomenon from every unit under test could be graphed and logged.

.jpg)

.jpg)

An automated system made up of an air compressor, actuators, solenoids and NI relay modules was designed and commissioned to automate opening the refrigerator's door as prescribed by the Energy star test.

The lab techs were able to configure the ON an OFF timing of the solenoid through a process controller therefore controlling the sequence of the door opening and closing automatically.

This automated system replaced a manual task which previously was occupying the entire day of a lab tech.